|

|

No. 76 June 2011 |

| |

Applied Technology

Turning Wastes into Treasures

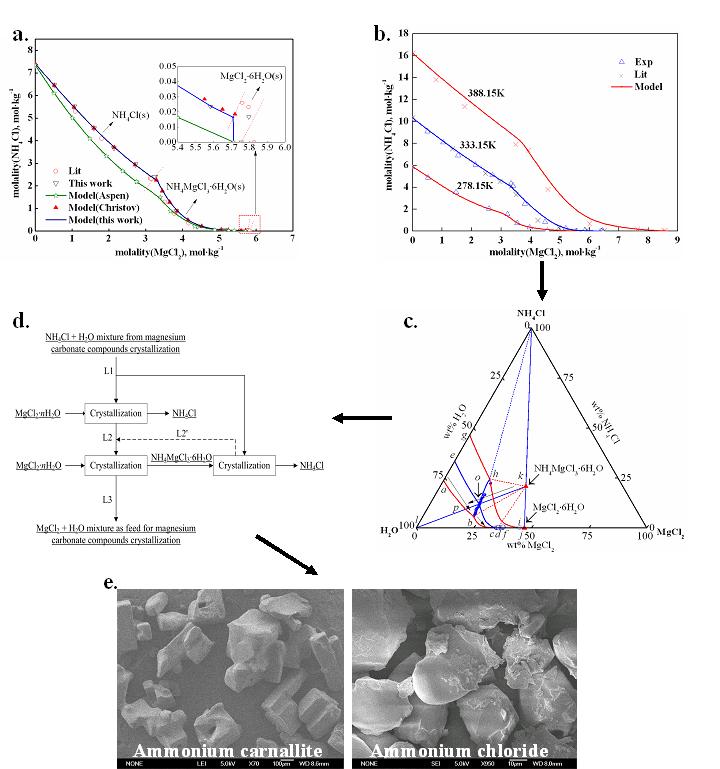

China boasts its rich resources in the sea and lake brine, which contain sodium, potassium, lithium and magnesium, etc. Such resources have long been widely used in the traditional chemical industry, and contributed greatly to the economic development. However, the magnesium chloride wastes, which are produced as by-products from the chemical production, are discharged directly into the lakes or elsewhere. Such wastes have resulted in serious pollution, which remained as a big challenge to not only the environment, but the utilization of natural resources. Based on basic research in the thermodynamics and phase diagram of saline water system, a group led by Prof. Li Zhibao of the Institute of Process Engineering has successfully put forward a combined solution, a technology to use the brine of magnesium chloride to make and prepare high-purity magnesium oxide and jointly produce ammonium chloride. This technology uses ammonium bicarbonate precipitation to segregate magnesium from brine, obtain magnesium carbonate hydrate and then produce magnesium oxide by calcining the hydrate. It also uses the salting-out effect of magnesium chloride to recycle all the ammonium chloride in the ammonium-rich wastes after precipitation of magnesium and form the circulation of materials, thus solving the problem of sewage discharge during the production process of magnesium oxide. This technology with low cost and high additional value has the advantages of energy saving and is friendly to the environment, in the meantime it provides a viable technical approach for the sustainable utilization of the resources in the salt lakes. Related results were published on AIChE Journal (2011; 57:1595-1606).

Modular DNA Analysis System May Work Soon

On Apr. 1st, a modular DNA analysis system, a project of the Major Scientific Facility Program of CAS jointly undertaken by the Beijing Institute of Genomics and the Institute of Semiconductors, passed the acceptance check. The completion of this project marks that China has formed its own intellectual property rights in terms of high-throughput DNA sequencing technology and its system prototype, which clearly indicated that China has made a breakthrough in home-made sophisticated life science instruments and equipment in respects of the development for the second-generation DNA sequencing instruments. Enabling China¡¯s own DNA sequencing capability to match the performance of international mainstream equipment, the results have important specific values in terms of basic and applied research in fields of genomics, bioinformatics and even life sciences, and many more. This project group is now sparing no effort to fully realize the systematic functions of this equipment.

New Advances in High-temperature Electrolysis

Finding large-scale and low-cost hydrogen source is crucial to the exploration of hydrogen power. For the time being, over 90% of hydrogen is produced from natural gas. Solar energy and wind energy have been boosting their share in energy sources structure in the recent decade, but the discontinuity of solar and wind power limits their share in further growth. Hydrogen is preferable for renewable energy storage of excessive solar and wind energy. A group of researchers from the Fuel Cell and Energy Technology (FCET) Division at the Ningbo Institute of Material Technology and Engineering, CAS, announced new progress in high temperature electrolysis (HTE) process after two year research based on their extensive work on solid oxide fuel cells (SOFCs). The researchers used a standard SOFC stack module developed by NIMTE for HTE. The stack contained 30 unit cells with an effective area of 70cm2. The hydrogen electrode of the stack was fed with H2£¨0.5L/min£©and steam(2.24L/min, 1atm, 298K) where H2 was used as protective gas medium. The stack was subjected to HTE at 800oC in the mode of solid oxide electrolyzer cell (SOEC) for more than 800h without any degradation. The electrolysis conversion rate was calculated 73.5% by measuring the input and output steam mass of the stack, and the hydrogen production rate was over 98.7NL/h.

copyright © 1998-2015

CAS Newsletter Editorial Board: 52, Sanlihe Road, Beijing 100864,

CHINA

Email: slmi@cashq.ac.cn