Polymer nanocomposites is one of the most emergent fields in material science and engineering. Novel carbon-based materials, represented by carbon nanotubes (CNTs) and graphene, have attracted a lot of attention in the development of polymer nanocomposites. The dispersion and stabilization of nanoparticles into a polymer matrix are the key issues for the preparation of polymer nanocomposites. The construction of foam-like architecture provides an alternative for preparation of high performance polymer nanocomposites. The chemical vapor deposition (CVD) method is an effective strategy to develop such structures; however, this method generally uses metal foam as a template, and the substrate has to be removed by strong acid after preparation, leading to some negative effects on the structure and properties of nanoparticles.

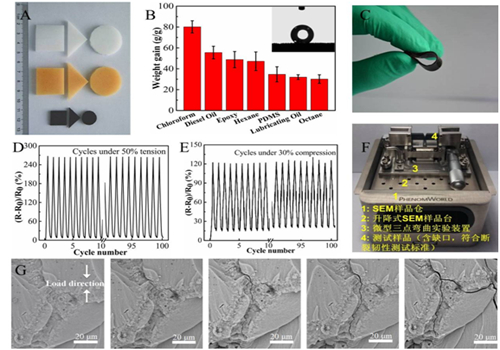

A team working on composite materials led by Professor Ma Pengcheng at the Xinjiang Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, has developed a new strategy to prepare CNT foam by using commercial polymer foam as a template. Unlike the traditional ones, the new method combines a 3-in-1 step, i.e., decomposition/removal of the polymer template, generation of the metal catalyst and CNT growth, for efficient and scaled-up production of CNT foam. The developed material shows a hydrophobic property and can absorb a variety of polymers and organic compounds of 30 to 80 times its own weight, allowing convenient preparation of nanocomposites and eliminating the problems associated with the dispersion of nanofillers in the polymer matrix. The developed method also shows excellent applicability. For example, when taking cotton or graphene foam as a template, CNT materials with respectively hierarchical or hybrid structures were achieved.

By utilizing the porous structure and excellent adsorption performance of foam, three dimensional polymer nanocomposites reinforced with CNT foam were fabricated via the self-infusion of polydimethylsiloxane. The researchers studied the mechanical and electrical properties of nanocomposites, and found that the material exhibits a piezoresistive behavior under mechanical deformation. A prototype flexible sensor was designed based on the nanocomposites, and the device was sensitive to both compressive and tensile strains. Such performance could be sustained with outstanding stability during cyclic runs. The operating principle of the sensor was investigated as well by using a specially-made fixture, and the results revealed that the device’s piezoresistivity was closely related to the changes in the deformation of the constructed cells in the CNT foam, which resulted in the initiation and propagation of cracking/damage in the nanocomposites. The combination of the rapid response and excellent flexibility/stability of three-dimensional polymer nanocomposites meant that the developed sensor could monitor the motion of a finger and serve as an electronic skin to display the distribution of pressure, suggesting the great potential of the nanocomposites for applications in wearable and flexible electronics, energy storage and so on.

Part of the research outputs has been patented, and the results on the flexible sensor using three dimensional polymer nanocomposites were published in Composites Science and Technology.

For more information, please contact:

Prof. Ma Pengcheng

E-mail: mapc@ms.xjb.ac.cn; mapc2004@126.com

Source: Xinjiang Technical Institute of Physics and Chemistry CAS