Metals usually exhibit high coefficients of friction (COF) under dry sliding, generally ranging from 0.6 to 1.2. The primary reason is sliding-induced plastic deformation of near-surface material, especially for ductile metals under high loads, resulting in surface roughening and formation of delaminating tribo-layers.

Lowering COFs of metals under dry sliding is of great technological significance for improving the reliability and efficiency of metal contacts in engineering applications ranging from heavy-load gears to mining and rolling machines, although it is technically challenging.

Refining metals’ grains into nano-scale was expected to reduce COFs as it elevates the hardness by many times. But no reduction in COF was observed in many nano-grained (NG) metals compared with their coarse grained (CG) counterparts under high-load/speed sliding. This originates from the very limited plastic deformation ability of NG structures, which becomes a bottleneck problem to complete in reducing COF of metals.

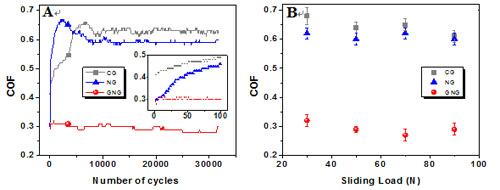

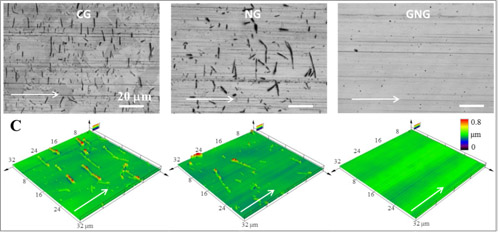

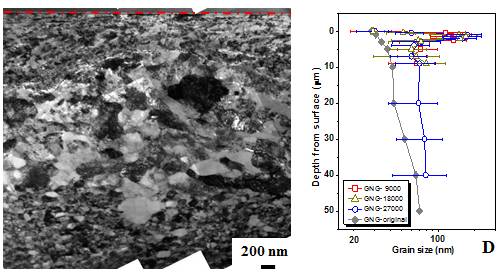

In their recent work, the research group headed by Prof. Lu Ke, member of CAS at Shenyang National Laboratory for Materials Science (SYNL), Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS), achieved a gradient nano-grained (GNG) surface layer in Cu-Ag alloy, which enables a significant reduction in COF under high-load dry sliding (Fig.1A&B), from 0.64 (CG samples) to 0.29 under a load of 50 N. The scar surface is smooth without any cracks or pile-up (Fig.1C), either after a single or repeated sliding. The surface roughness along the sliding direction is identical to that of the original sample, which indicates that the sliding-induced plastic strain is well accommodated by the GNG structure without generating strain localization. The unprecedented low COF originates from the stable gradient nanostructures that can accommodate large plastic strains under repeated sliding for more than 30,000 cycles. A mechanical-driven grain boundary migration process with a concomitant grain growth (Fig. 1D) dominates plastic deformation of the GNG structure.

The superior stability of the GNG structure against sliding-induced surface roughening and delamination provides a novel strategy for enhancing wear resistance of metals and alloys. The finding may possess tremendous potential for technological applications in contact of metals.

The relevant work entitled “Lowering coefficient of friction in Cu alloys with stable gradient nanostructures” was reported in Science Advances.

Fig. 1. (A) Variation of COFs with sliding cycles for the CG, NG, and GNG Cu-Ag samples sliding against WC-Co balls under a load of 50 N, a slide stroke of 1 mm and a velocity of 10 mm/s. Inset shows COFs during the initial 100 cycles. (B) Variations of the steady-state COFs with the applied load for the three samples. (C) Confocal laser microscopy images and 3-D profiles for surface morphologies of the CG, NG, and GNG Cu-Ag samples after a single sliding, respectively. (D) A typical cross-sectional TEM image of the subsurface layer in the GNG sample after sliding for 27,000 cycles and the variation of the mean grain sizes along depth in the GNG samples before and after sliding for 9,000, 18,000, and 27,000 cycles, respectively. (Image by IMR)

Contact:

Associate Prof. Han Zhong

Email: zhonghan@imr.ac.cn

Institute of Metal Research, Chinese Academy of Sciences